Tube Launched Electric Powered Fixed Wing UAV

AAE 451: Aircraft Design (Senior Design Project)

Task: The challenge was to design, build, and flight test a tube-launched, electric powered, remotely piloted fixed-winged aircraft that can satisfy the mission requirements. Details of the requirements can be found in the project's Request for Proposal (RFP).

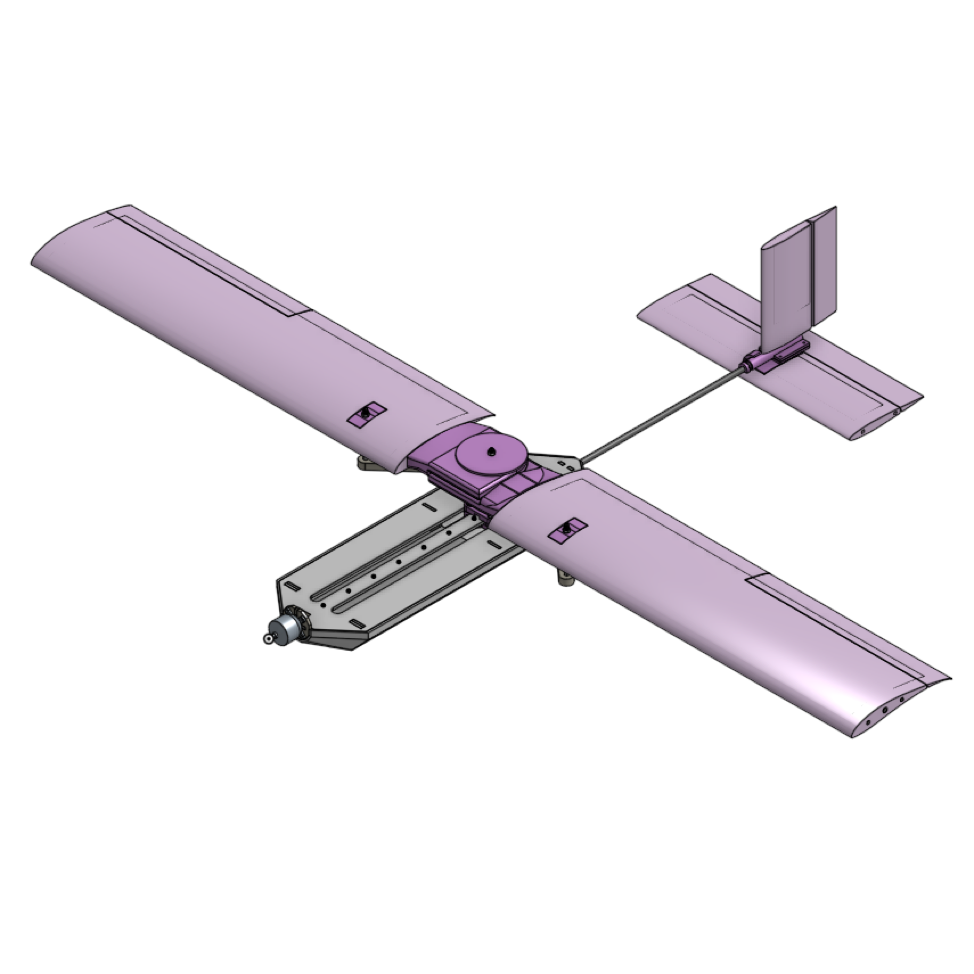

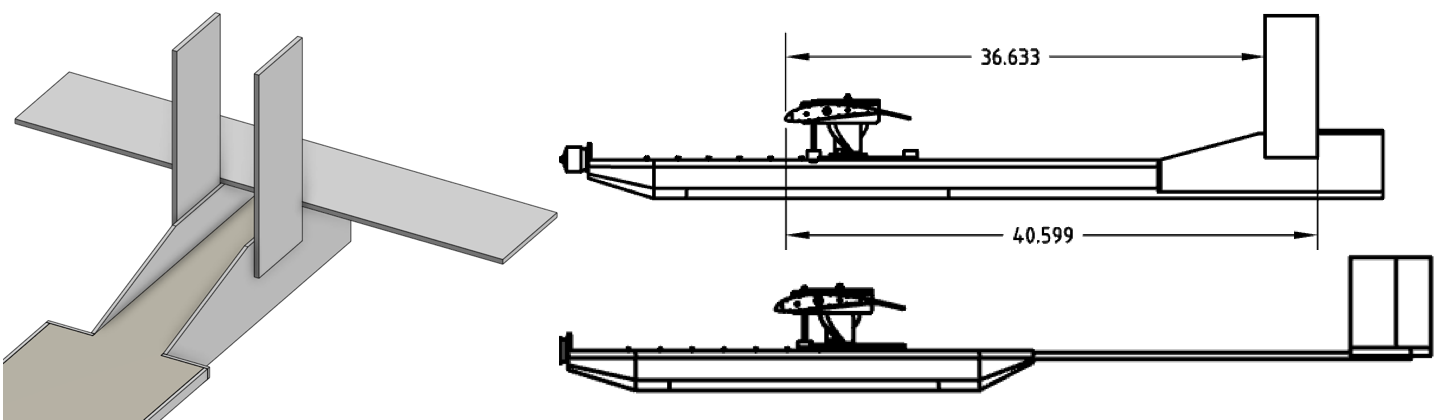

The final aircraft design (left) and the aircraft that flew (right)

Important Contributions

Aerodynamic Design

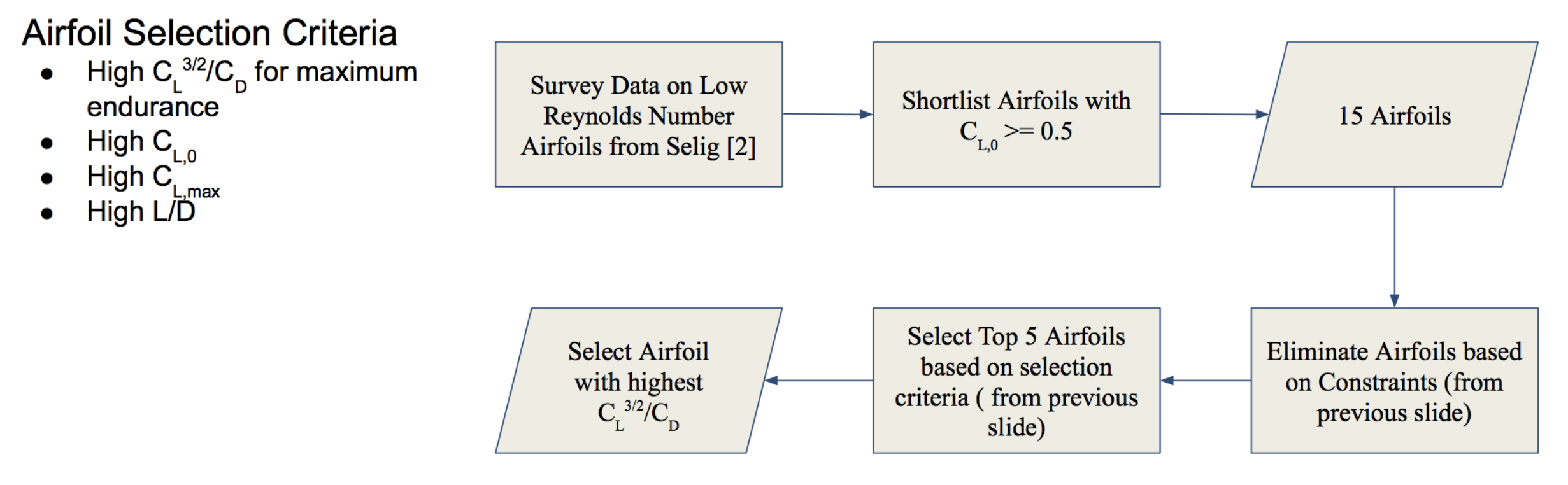

Since the challenge was to tube-launch a fixed-wing aircraft, and the tube size was specified, this directly put constraints

on the size of the wings. The wings had to be within span and chord limits that would allow it to fit in the launch tube.

Thus, selecting a good airfoil became paramount to the success of our UAV since a good airfoil would give more room for changes

in other aspects of the wing design (like span). In order to select the airfoil, I came up with a selection process,

depicted in the flowchart, along with certain criteria that can be seen below. Based on this selection process, the

Selig S1210

airfoil was selected. Details can be found in the design report.

Criteria for selecting an airfoil and flowchart depicting the airfoil selection process.

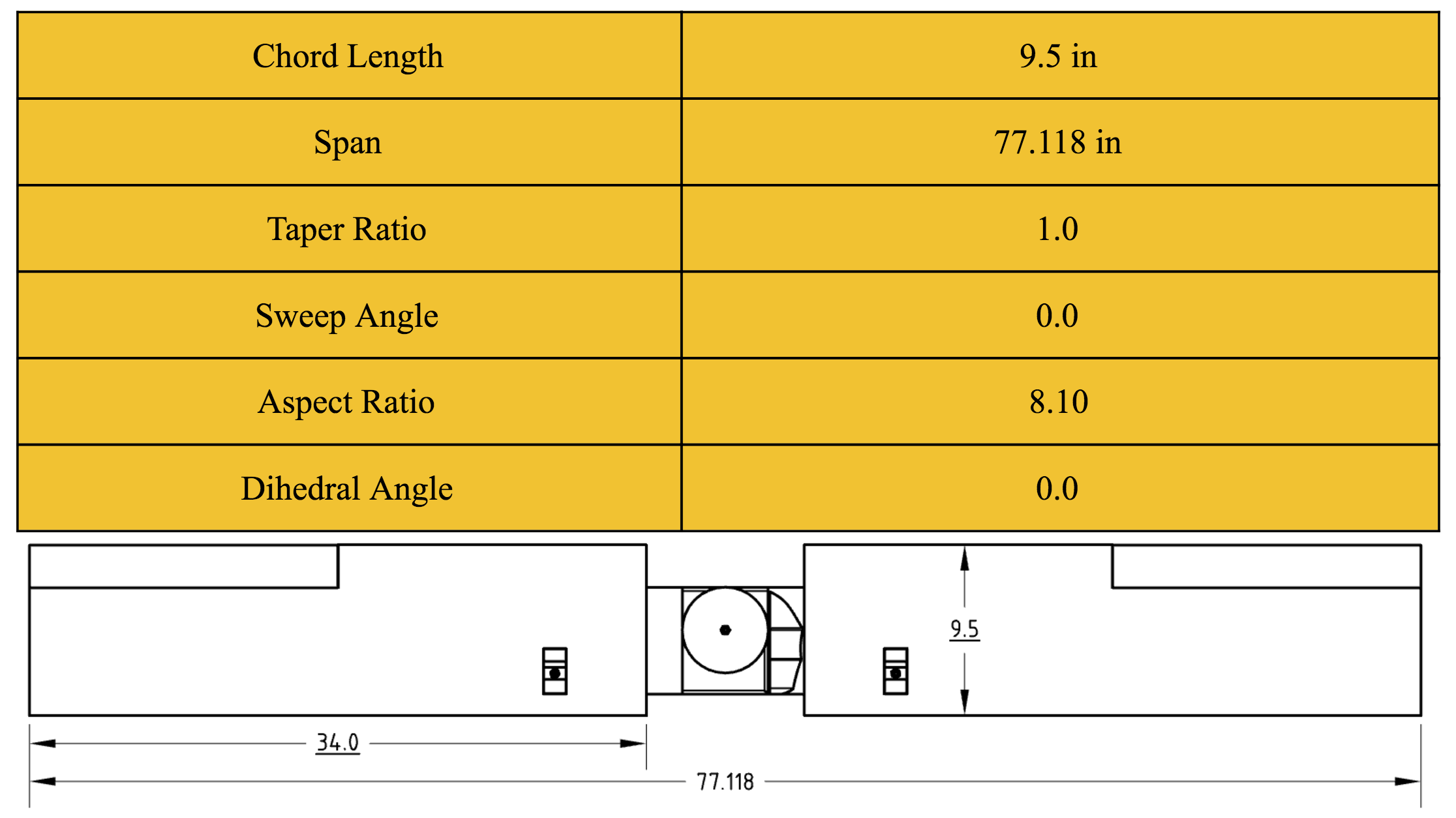

Other aspects of the wing design were dictated by tube-size and manufacturing constraints. Details of the 3D wing can be seen here.

XFLR5 & CFD Analysis

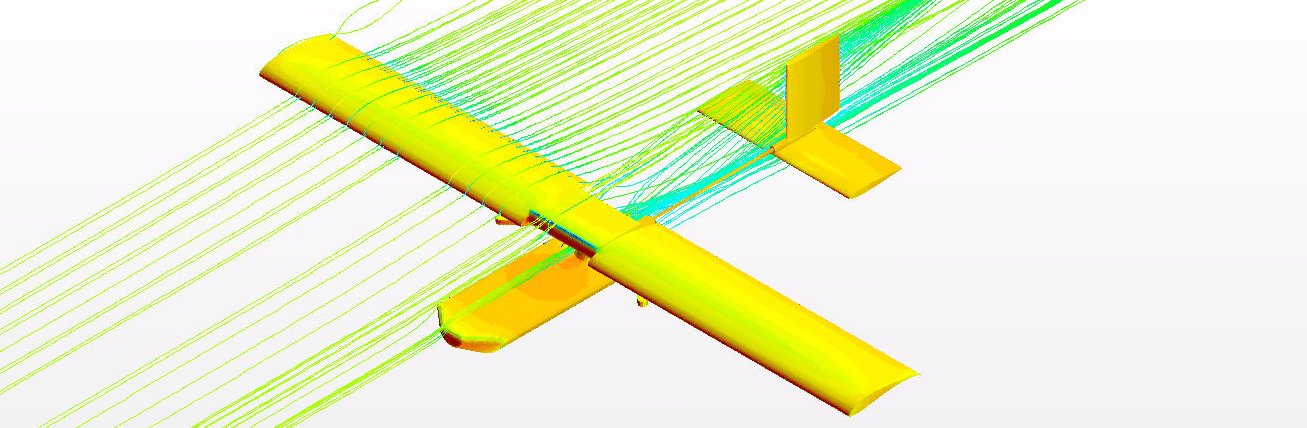

During the design and analysis phase it was important to

analyze the aerodynamic characteristics of the UAV so other sub-systems, especially controls, could work on their

design and use the correct aerodynamic properties of the aircraft. XFLR5 was the primary analysis tool used to determine

airfoil/wing performance in conditions that we expected the UAV to fly in. Multiple designs were tested before the final

design was selected. Despite the quick, and somewhat reliable lift estimates provided by XFLR5, it did not provide

reliable estimates of drag. Therefore, I ran a CFD analysis of the final design simulating flow over different angles

of attack in order to determine the necessary aerodynamic coefficients. Once again, I employed macros to increase my

productivity. A snapshot of one of the simulations can be seen below.

CFD simulation of final aircraft design with streamlines and pressure distribution over the UAV surface.

Tail Design (Individual Trade Study)

As part of the deliverables for the class

was an Individual Trade Study where each student would study the merits and demerits of a possible modification that could

improve the final design. Since our tail design was rather clumsy and bulky, I took up the study of trade-off between

different tail designs.

The original tail (pictured below) was made of wood and foam and needed a complex folding

mechanism for the stabilizers to fit in the launch tube. Instead of this I proposed attaching a boom to mount the

stabilizers giving us more room inside the tube to fit the vertical and horizontal stabilizers. A boom also gave us more

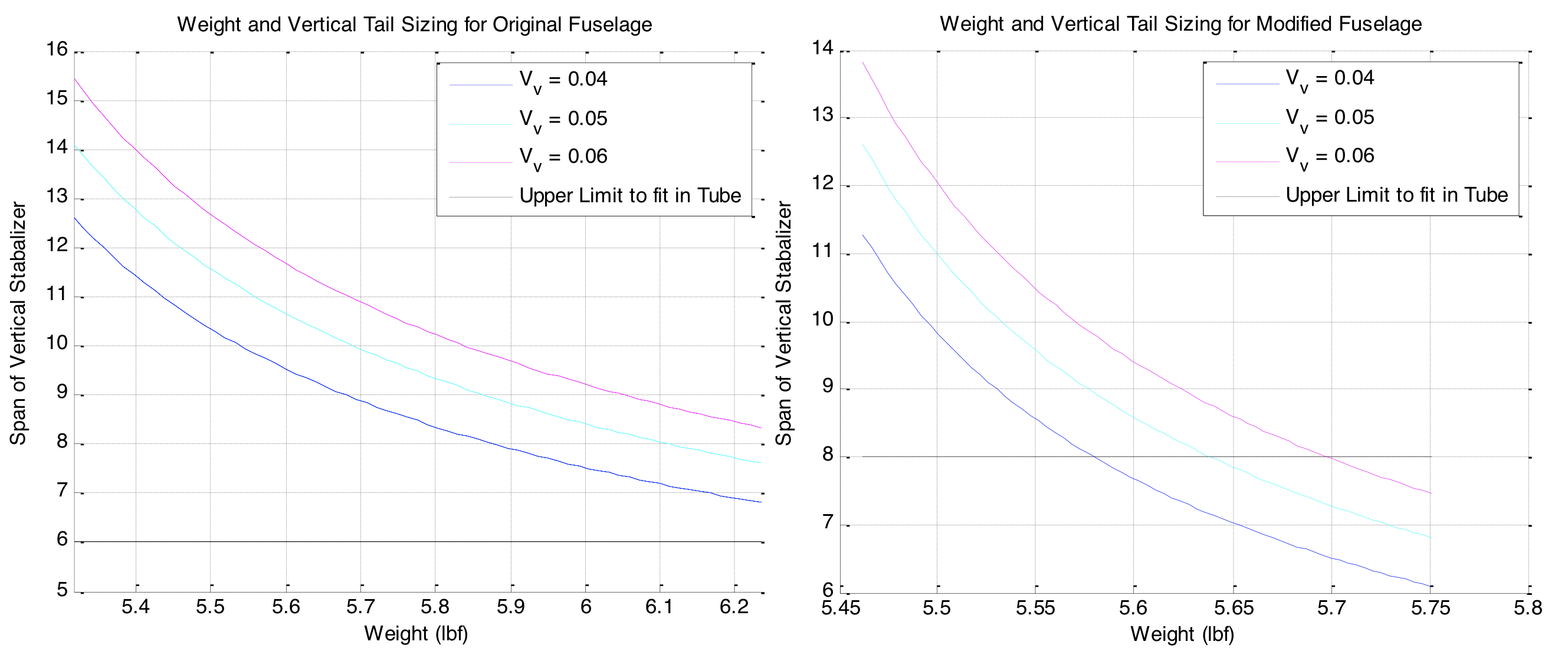

flexibility with changing the moment arm for the stabilizers without adding too much weight. I plotted the weight vs

length of moment arm (that affects the volume coefficient, VV, in the graphs below) in order to evaluate the

designs. From the plots, it's clear that there is a reduction in weight with the new design and therefore the new design

was implemented on the final aircraft. Details of the analysis and its impact can be found in

this report.

Original tail design (left and top right) and the alternative design evaluated (bottom right)

Vertical stabilizer sizing vs Weight for Original (left) and alternative (right) design for different volume coefficients.

Equations of Motion for launch and constraint diagram

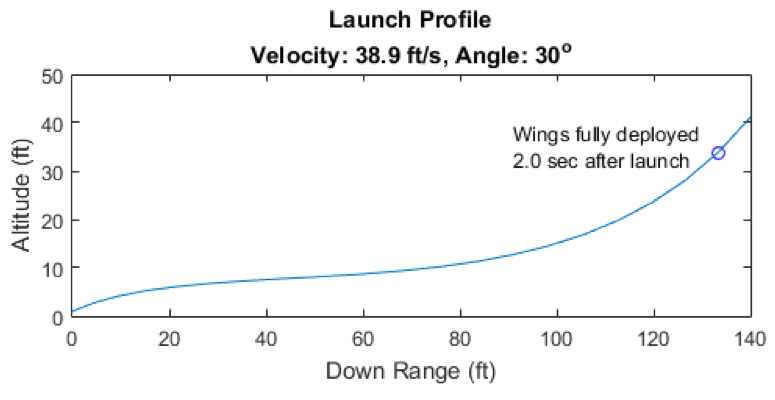

Since the launch section

of the flight profile is not common, we could not find the EOMs that would govern the vehicle dynamics in that phase of flight.

In order to be confident about our design, we decided to derive the EOMs and calculate the flight profile using MATLAB.

I worked with a teammate, Daniel Ellinwood, to derive the EOMs and plot the flight profile that can be seen below.

This analysis enabled us to tweak our launch system to give us better ground clearance in the launch phase.

Earlier in the

design process I had performed a similar analysis to determine the power loading and wing loading constraints imposed by the

launch system.

Estimated flight profile upon launch from tube calculated based on EOMs we derived.

While these were my design contributions to the project, every member of the team was involved in the build phase. Having worked with composite materials before (at Formula SAE), I lead the team's layups of fibre glass on the foam wings. In the build phase I learnt a lot about dealing with other materials, and some of the practical aspects of UAV building that I previously was not aware of. When the UAV took flight, that was the most satisfying moment of my life and reinforced my will to continue working as an engineer and to transform the world.

The first flight test of the UAV where is successfully took flight. Out of the 4 teams in the class, only our team had a successful flight. This was the happiest moment of my life, and is a testament of my desire to be an engineer.

For more details about the UAV and the project please refer to the Design Report.

Testimonials

Each semester, Purdue University School Aeronautics and Astronautics offers an Aircraft Design course, AAE 451, aimed to

expose students to aircraft design principles, emerging aerospace technologies, advanced manufacturing operations, and

variant aerospace platforms relevant to the aerospace industry today. During the fall semester especially, AAE 451

is oriented to explore small unmanned aircraft systems (SUAS) design and select low-altitude operations.

Each student is given the opportunity to explore and grow in fundamental aerospace disciplines (e.g. aerodynamics,

dynamics and controls, propulsion, structures) and project management to produce efficient aerospace products on-demand.

Ujjwal was a student from the fall 2016 semester of AAE 451 and he exemplified high aptitude for design and project

management during team and individual assessments throughout the course. His team consisted of the most diverse students

in the class. Despite communication challenges, his team was able to produce the most innovative aircraft of the course.

Ujjwal and his teammates produced an aircraft consisting of a foamboard fuselage, fiberglass reinforced Styrofoam wings,

commercial-of-the-shelf (COTS) propulsion system [selected to design specifications], and 3-D printed mechanisms and parts.

Ujjwal and his teammates address the Request for Proposal (RFP) for the course to produce an aircraft with a deployable wing

capable of tube-launch operations. He and his teammates received satisfactory in majority of the deliverable categories and

was the only team of six teams total to achieve flight on the first day of testing. Ujjwal displayed great poise and leadership

to propel his team to achieve the highest marks of all teams participating in the RFP despite aircraft redesign due to

destruction during pre-flight.

Ujjwal, by the end of the course, became more proficient in aircraft design and project

management and is well-equipped to make a difference for any aerospace related organization in the future.

Testimonial on letter head

-Brandon Sells, Teaching Assistant

Ujjwal was a fantastic contributor to our senior design team. In particular,

his work on the aerodynamics of our tube-launched UAV was extremely thorough,

and he was able to present his analysis clearly in both formal and informal settings.

In addition to his technical contributions to the project, Ujjwal also greatly contributed

to the overall team experience with a positive attitude and willingness to help beyond his

own responsibilities. I will fondly remember all of the incredibly late nights that led

to the successful launch of our aircraft, and would jump at the chance to work with Ujjwal

again in the future.

-Alex Sechtig, Teammate

Ujjwal was one of the best members of the team. He worked smart and produced

quality analyses quickly. Our team was very fortunate that he was a member because I am sure our project

would not have concluded so well otherwise.

-Daniel Ellinwood, Teammate